It's a New Day in Public Health.

The Florida Department of Health works to protect, promote, and improve the health of all people in Florida through integrated state, county, and community efforts.

Self Assessment Inspections

Questions about drywall?

The Florida Department of Health developed this self-assessment guide to make it easier for homeowners to determine if their home meets the criteria for a possible case of drywall associated corrosion as specified in our current case definition. The evaluation steps included here are designed to be taken by a homeowner or building trades professional without any special training in materials analysis or environmental sampling. These steps focus on the appearance of discoloration and corrosion of metals consistent with the presence of reduced sulfur gasses.

You must be able answer yes to each indicator before you meet the possible case definition. To reach an increased level of confidence that a home suffers from drywall associated corrosion, we recommend materials analysis by trained professionals as described in the case definition.

- Indicator 1 – Age of Home

- Indicator 2 – Blackening corrosion of air conditioning evaporator coil or repeated A/C evaporator coil failure

- Indicator 3 – Observed metal corrosion

- Final Analysis

The problem of drywall associated corrosion is known to occur in homes built, renovated or repaired with drywall replacement since 2001.

Assessment of indicator 1 (Yes/No)

Was the house built, renovated or repaired with drywall replacement during the time period of concern? Yes or No

This corrosion can result in refrigerant leakage making it impossible to cool the home requiring evaporator coil replacement. This type of corrosion is characterized by the blackening of copper in and around the air handler unit. Note that accessing the A/C coils may be dangerous, and should be performed by a licensed A/C contractor. There are three ways to determine if your home meets this indicator:

Option 1: Repeated A/C evaporator coil failure

Coil failures indicative of this corrosion problem typically occur every 6-14 months, instead of the normal 10 to 20 years. If the A/C evaporator coil has been replaced, contact the repair company to see if they have any notes that indicate the condition of the coil during replacement. Ask the repair company if copper in the evaporator coil had turned black or were there signs of a different coil failure mechanism.

Option 2: For air handling units located in an inside mechanical closet or in the garage.

Look to see if the compressed refrigerant line going into the air handler has a black appearance, typical of sulfur corrosion. This copper line is approximately ¼ inch in diameter and can be easily viewed without opening the air handling unit (AHU) or removing any panels. If the air handler is in an interior closet or in the garage, go to it and look at the un-insulated copper line going into the air handler. Compare it to the image below. The image below shows the normal copper color which changes with age and normal exposure to the environment compared to the color of copper that has been exposed to corrosive sulfide gasses. Click on the image for a larger view.

Normal copper color vs Sulfide Corroded Copper Color

Option 3: For air handlers in any location

It is less likely to find the blackened copper corrosion on the un-insulated refrigerant line in homes with corrosive drywall when the air handler is located in the attic or crawlspace. We recommend you have a state licensed air conditioning contractor evaluate copper corrosion on the coils inside these units. You may also have a a contractor evaluate the coils for copper corrosion when the air handler is in a closet or garage.The image below shows the normal copper color which changes with age and normal exposure to the environment compared to the color of copper that has been exposed to corrosive sulfide gasses. Click on the image for a larger view.

Normal Copper Coil vs Sulfide Corroded Copper Coil

Assessment of indicator 2 (Yes/No)

Was blackening corrosion found on copper components of the air handler or have there been multiple A/C evaporator replacements? Yes or No

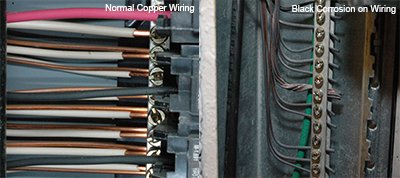

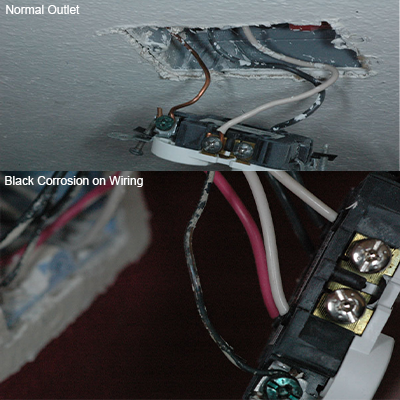

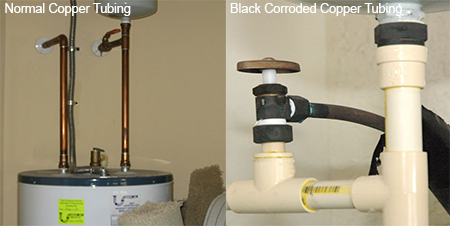

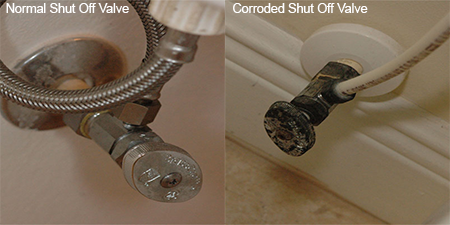

Electrical wiring as well as other copper, silver and metal fixtures may exhibit sulfide corrosion when exposed to the reduced sulfur gases. Most of the following items may be examined by the homeowner: copper wires, ground wires, and electrical connectors; un-insulated and un-coated copper pipes and fittings, chrome-plated bathroom fixtures, silver and copper jewelry and mirror backing in bathrooms.

Due to the electrical shock hazard presented by live wires, we recommend you hire a licensed electrician to inspect electrical system components.

Examples of Electrical wiring/system corrosion indicators

Examples of Copper Tubing and Fixtures

For additional examples of metal corrosion, see the photos in the case definition.

Assessment of indicator 3 (Yes/No)

Did you find blackening or signs of sulfur like corrosion on one or more of the listed items? Yes or No

If you answered 'Yes' to all three of the previous questions, the home meets our criteria for a possible case of drywall associated corrosion. Before proceeding to remediate your home, we recommend you have your home evaluated by a trained professional to see if your home meets case definition criteria 3 for a confirmed case.

Connect with DOH